Maglev Turbo Blower

Blower is used to compress air by centrifugal movement of the rotor, then transport the compressed air to the desired place. Maglev Turbo Blower uses active magnetic bearing and high-speed permanent magnet synchronous motors(PMSM)technology, which is a new type of energy-saving and environmentally friendly product through integrated design.

Energy conservation:

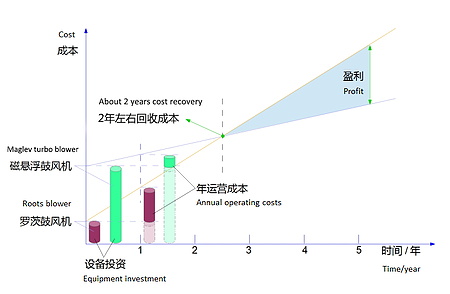

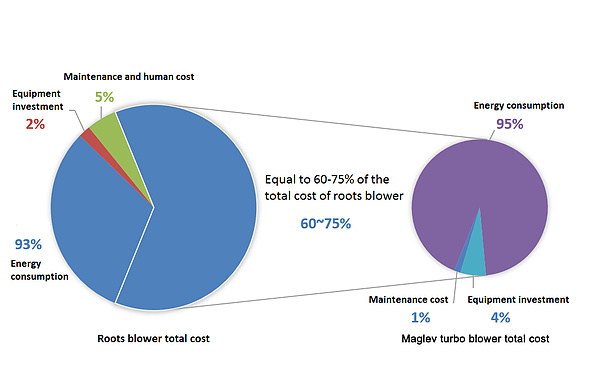

Compared with roots blower, each set can save more than 300,000 kW/h electricity every year.In comparison to traditional blower, the efficiency of Maglev turbo blower is improved by more than 30%.

Environmental protection:

With calculation of the Maglev turbo blower with capacity of 150hp, equal to reduction of emission of 275 tons carbon dioxide.

The Maglev turbo blower requires no lubrication and the airs it transmitted are clean and no pollution.

The Maglev turbo blower generate low noise and no impact the surrounding office and living environment.

Advanced technology:

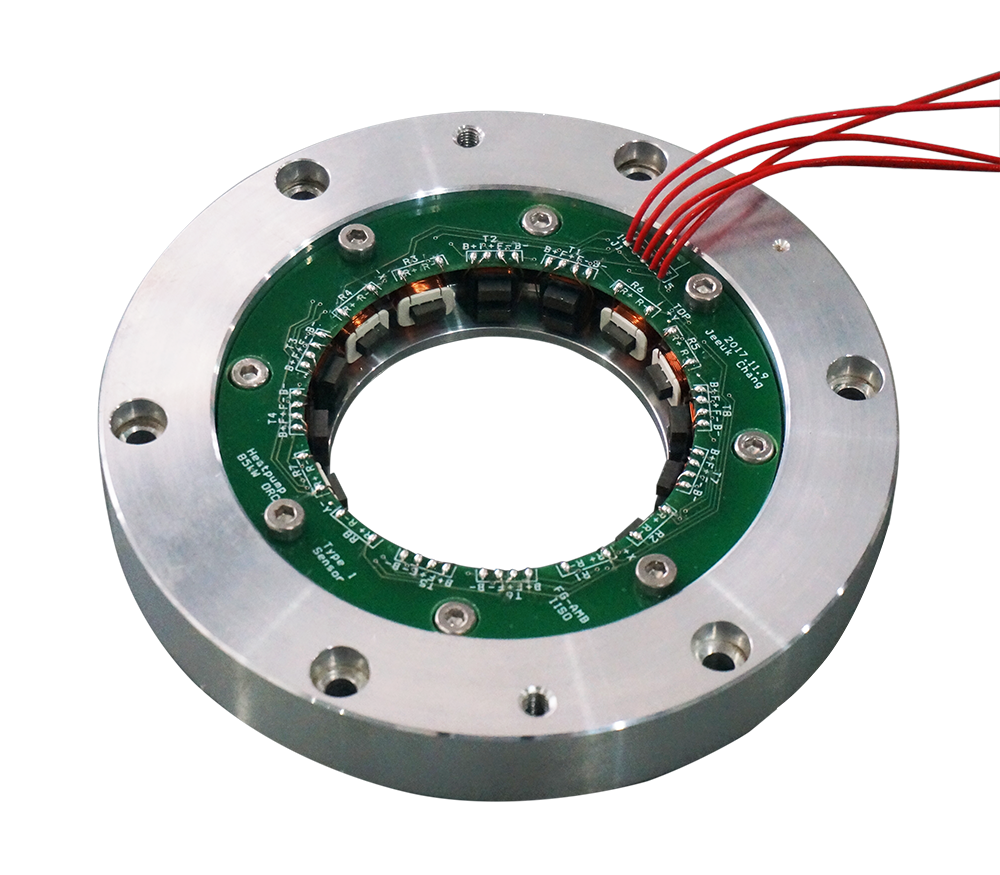

The active magnetic bearing system is adopted without abrasion and no need of lubrication system.

High-performance frequency converter is adopted to control the revolving speed and multiple control modes are available for choice.

The advanced control system is adopted to monitor the operating status and is able to conduct remote control and there is no need to designate personnel for guarding.

Fully enclosed air cooling system are employed for heat dissipation of motor so as to guarantee the air blower stays at a stable and highly efficient operating status.

The modular design makes the maintenance convenient and fast.

low operating cost:

The maintenance of AMB turbo blower is easy and only replacement of filter is required.

Maglev turbo blower requires no lubrication system, save the cost for lubricant.

Compact design, save space.

Low maintenance cost, timely after-sale service.

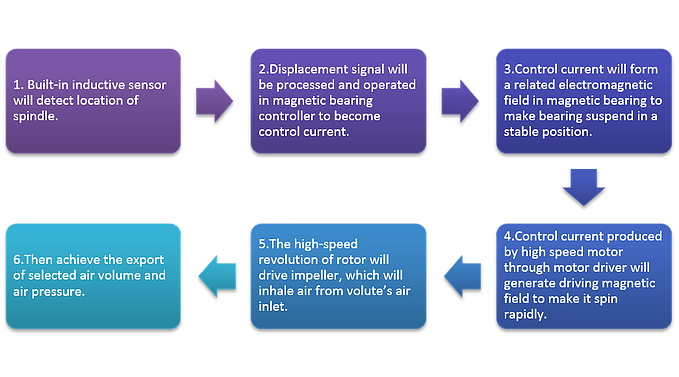

Working Principle

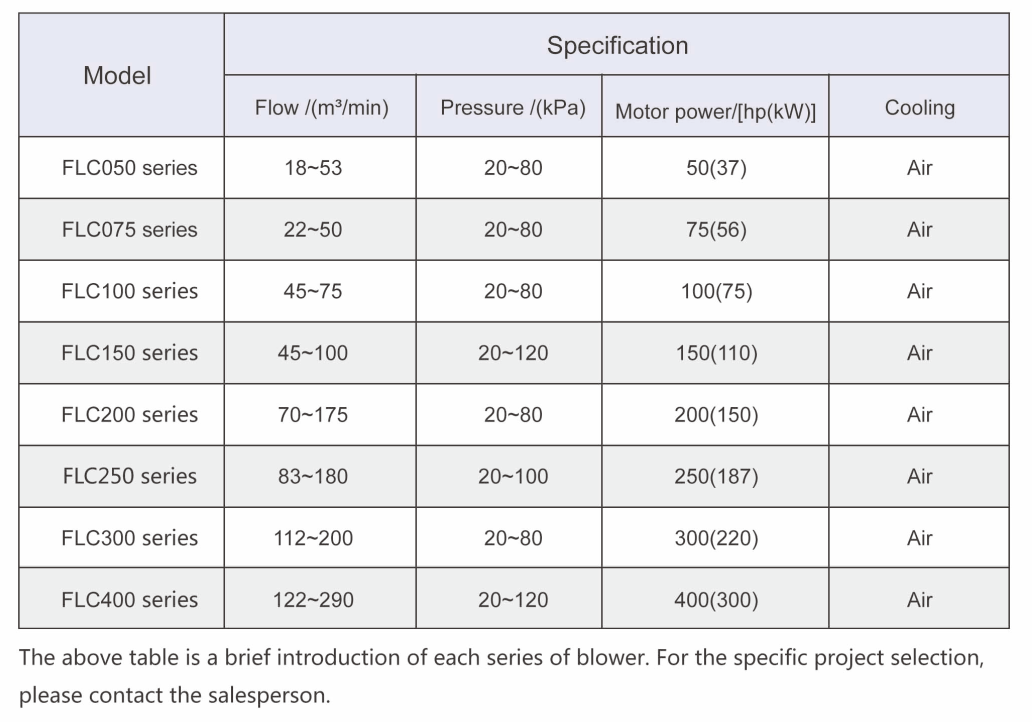

Specification:

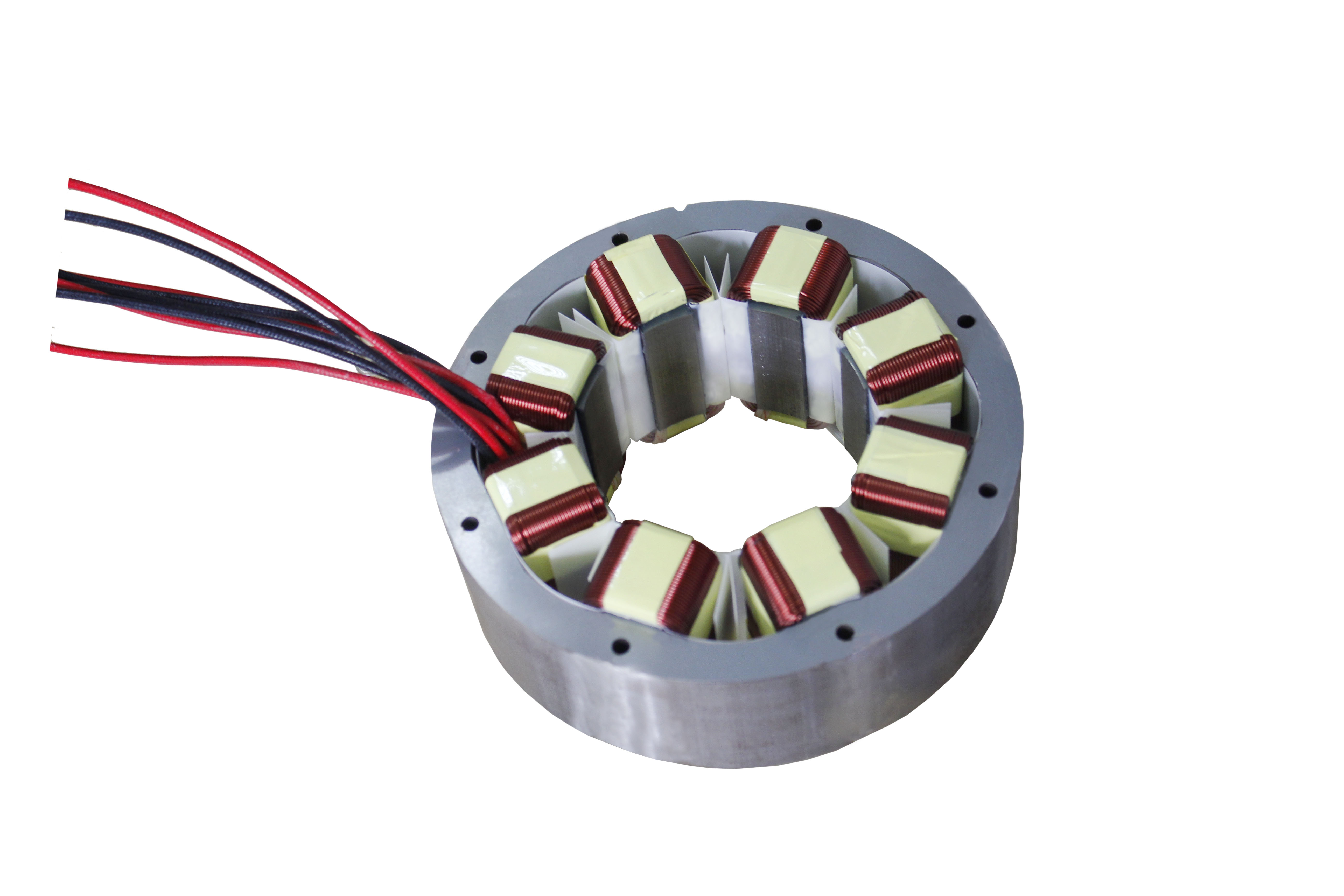

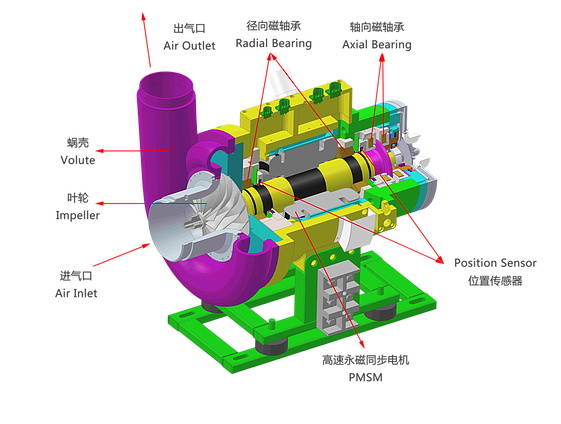

Core Components

Product Structure

Overall Structure